From Compliance to Application — Everything You Need to Know

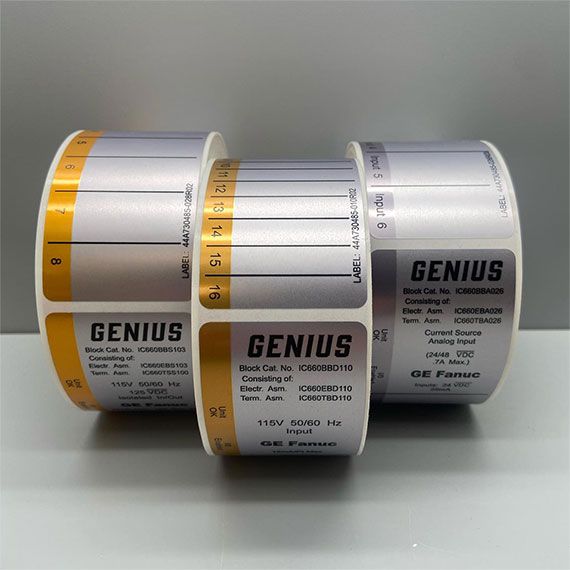

When it comes to the automotive and industrial sectors, labels aren’t just branding elements—they’re essential tools for safety, compliance, maintenance, and traceability. A missing or non-compliant label can result in hefty fines, equipment failure, or safety risks. That’s why Star Tag & Label specializes in producing automotive and industrial labels engineered to meet exacting standards and endure extreme environments.

Whether you’re labeling batteries, electrical components, industrial machinery, or chemicals, this guide covers essential requirements, design considerations, application tips, and equipment to ensure your labels meet every regulation—and perform for the long haul.

Why Automotive & Industrial Labels Matter

Labels in industrial and automotive settings serve critical functions:

- Communicating safety warnings

- Supporting regulatory compliance

- Enabling inventory control and traceability

- Providing maintenance or operating instructions

- Ensuring legal liability protection

Over 22% of all product detentions in the U.S. are due to labeling issues. If your label isn’t printed or applied to spec, it can lead to penalties, failed inspections, or product recalls.

Key Regulatory Standards You Must Meet

Automotive Industry Action Group (AIAG) standards include:

- Barcode height and quiet zones

- Text size and font selection

- Symbol positioning

- Label durability requirements

- Standard white background with black ink

Safety labels must meet ANSI Z535 requirements:

- ANSI Z535.1 – Defines official safety colors and Pantone® matches

- ANSI Z535.3 – Covers proper use of safety symbols

- ANSI Z535.4 – Governs layout, signal words, and label placement

Chemical labels must comply with OSHA’s GHS system:

- Use standard GHS pictograms

- Include a signal word like “DANGER” or “WARNING”

- Add hazard statements and precautionary measures

- Use multilingual formats if required

Industrial Label Design Best Practices

- Use polypropylene (BOPP) or polyester materials—never paper

- Apply UV- and abrasion-resistant coatings for longevity

- Use clear, simple text readable from intended distance

- Avoid dirty, oily, or uneven surfaces

- Avoid high-friction or heat zones unless labels are designed for them

- Consider bilingual or trilingual formats for diverse workforces

What to Include on Automotive Labels

- Manufacturer’s name and address

- Vehicle Identification Number (VIN)

- Maintenance instructions

- Safety warnings

- Emissions & fuel economy information

- Warranty terms

- Certification & compliance marks

- Barcodes or QR codes for manuals or recalls

Adhesive Matters: Don’t Overlook It

Adhesives must bond securely to metals, plastics, powder-coated, and painted surfaces despite:

- Heat or freezing temperatures

- Oil, solvents, or fluids

- UV exposure

- Moisture and condensation

Application Method: Hand vs. Machine

- Sheet labels – Low-volume, hand-applied

- Roll labels – High-speed automation

Top Label Applicators

- Quadrel Q60 – Rugged, high-speed automotive labeling

- Aesus EcoWrap – Wraparound labeling for bottles, drums, and cylinders

- Label-Aire 3138-N – Flexible wipe-on applicator for precision placement

How to Order from Star Tag & Label

We’ll ask key questions:

- What surface will the labels be applied to?

- Exposure to chemicals, heat, or sunlight?

- Application method—hand or machine?

- Volume pricing, JIT delivery, or warehousing needed?

- Barcodes, sequential numbering, or QR codes required?

Why Choose Star Tag & Label

- Durable materials and adhesives

- Barcode-ready and serialized options

- UV-, chemical-, and temperature-resistant finishes

- Fast lead times and exceptional service

Call (540) 389-6848 or Request a Custom Quote today! We invite you to leave us a review on Facebook or Google.

From certification labels to warning decals, chemical tags to engine part identifiers, Star Tag & Label delivers precision, performance, and peace of mind—on time, on budget, and always up to code.